Added Value

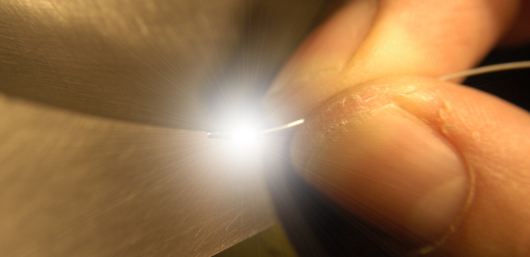

Our investment in state-of-the-art technology and in-house facilities such as laser welding, 3D surface scanning, heat treatment, etc, allows us to keep your tooling in tip-top condition and get your production line moving again if a mould gets damaged – no-one gets you moving faster.

Repair & Refurbishment

We offer a complete refurbishment service for tooling manufactured by other suppliers; European, The America’s or from the Far East – as well as our own, of course. At Beaubury we offer the total package of services for blow moulders and a very important part of this is ensuring that your moulds keep your production lines moving.

Modifications

Whether it’s a cosmetic change like adding, changing or removing cavity detail, or a technical change like changing to a new neck finish or base profile – talk to Beaubury.

Spare Mould Parts

A range of spare mould parts are stocked for most series’ of Sidel™ moulds as well as cutting sleeves, striker-plates, blow pins & tips.